Pioneering High-Recycled-Content Alloys

Aluminium stands at the forefront of sustainable innovation, offering a strong, durable, and infinitely recyclable solution for industries ranging from beverage packaging to automotive, aerospace, and beyond. In line with our 3×30 vision, we have set our sights on achieving an average recycled content of 75% by 2030.

Accelerating Our 3x30 Vision

To meet our target of 75% average recycled content, we are collaborating closely with customers across key sectors – beverage packaging, automotive, aerospace, and specialties. By developing high-recycled-content alloys that fulfill unique technical specifications, we aim to reduce the need for primary aluminium, minimize carbon emissions, and move the entire value chain toward a more circular model.

Building on Proven Success

Our beverage packaging sheet, one of our most extensive product lines already surpasses 80% recycled content. We are now refining a single-alloy beverage can design that we expect will push recycled content to over 90%. This exemplary achievement highlights our ability to meet demanding targets and demonstrate the true potential of aluminium in promoting circularity.

Aluminium - The Key to Circularity

Aluminium’s unique properties are central to its sustainability advantages. Unlike other materials, aluminium retains its strength and properties through repeated remelting and reprocessing. As a result, 75% of all aluminium ever produced is still in use today – an impressive figure underscoring its enduring value. Moreover, recycled aluminium requires approximately 95% less energy to produce compared to primary aluminium, contributing significantly to resource conservation.

Closing the Loop: Our Recycling Programs

Our closed-loop recycling initiatives are integral to our strategy. These programs collect aluminium scrap from original equipment manufacturers and transform it back into the same high-quality product. Beyond preserving the alloy’s value and integrity, this approach reduces the need for new primary aluminium, cuts transportation costs, lowers environmental impact, and ensures a stable material supply.

Expanding Recycling Capacity and Capabilities

Through ongoing investments, research, and collaborations, we continue to ramp up our recycling and casting capacities. This expansion not only decreases reliance on higher-carbon primary aluminium but also supports wider decarbonization efforts. In FY24 alone, we tolled 2,316 kilotons of recycled metal, including more than 80 billion used beverage cans. Since fiscal year 2012, we have invested approximately $700 million in recycling infrastructure, with additional projects underway to secure our leadership in this field.

The Road Ahead

Reaching 75% recycled aluminium content by 2030 requires sustained commitment and innovative thinking across the full spectrum of our operations. From designing advanced alloys to optimizing closed-loop systems, every step supports a circular, energy-efficient future. With proven successes behind us and more goals ahead, we remain dedicated to driving the aluminium industry toward higher recyclability and a reduced environmental footprint – paving the way for a truly sustainable future.

Explore More Success Stories

Aluminium Meal Trays: The Future of Sustainable Food Packaging

Novelis and Beiersdorf: Making an Icon More Sustainable

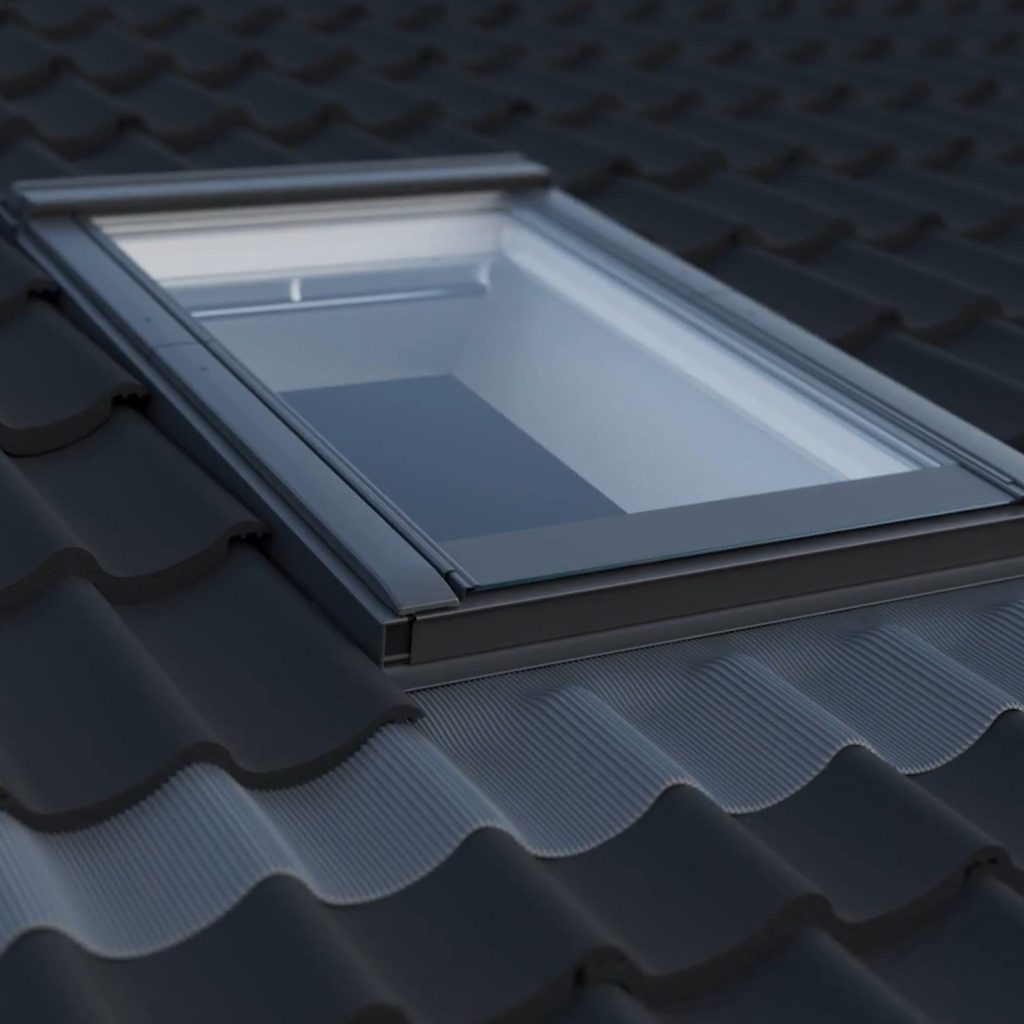

Novelis and VELUX: Partnering for Sustainable Innovation in Roof Windows